Capabilities

Profit

LeadershipTM

What is a Diagnostic Study?

Before embarking on a transformation initiative, SSA believes it is extremely important to understand the big picture of the client’s business such as their vision, short & long-term goals and the various strategic impediments that need to be addressed. This is accomplished by a detailed study of the performance metrics across the organizational value stream. The typical areas of study include:

- Demand and supply analysis.

- Assessment of operating expenses with a lens for profit leakages.

- Manufacturing system assessment for lead time, quality, and cost.

- Supply chain improvement opportunities.

- Product cost analysis and time to market.

The goal of the diagnostic study is to create an end to end from order to dispatch. A high-level Value Stream is developed highlighting issues, pain points and bottlenecks. Business-level metrics are measured and analyzed with a view of highlighting opportunities and pain areas. The approach helps to quickly pinpoint the priority areas within the organization that yield high-impact improvement opportunities.

Profit LeadershipTM Approach

SSA’s Profit LeadershipTM approach is based on SSA’s time-tested approach to profit maximisation. The “Moment of truth KPIs”, which show the true health of the organization. When we see through the lens of world-class performance metrics and compare the performance with the best-in-class industries from across diverse sectors, we realize there is a long way to go to reach world-class performance.

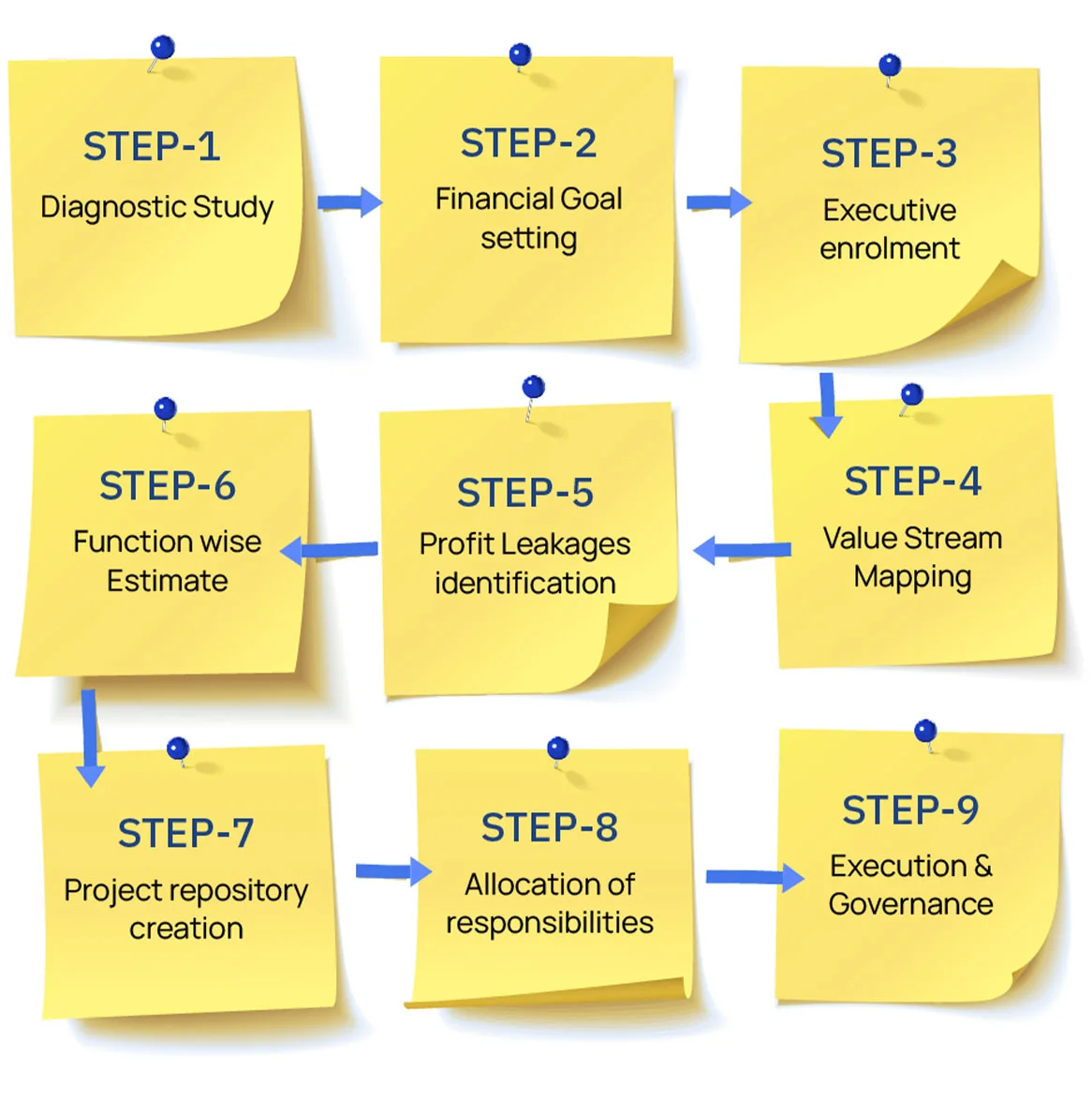

The steps are explained in brief as follows:

Having studied the as-is performance, we estimate the possible profit improvement and identify the high-impact items and their corresponding contribution to the profit enhancement.

With the data collected and analysed, the next step is to align the leadership executives for the profit improvement programs and achieve their buy-in for the project.

To get the big picture of the value flow from the requirement for a proposal to dispatching the material through mapping techniques as per value stream mapping. This exercise is carried out in the presence of the senior leadership team and the process owners to align their acceptance of the project's intention.

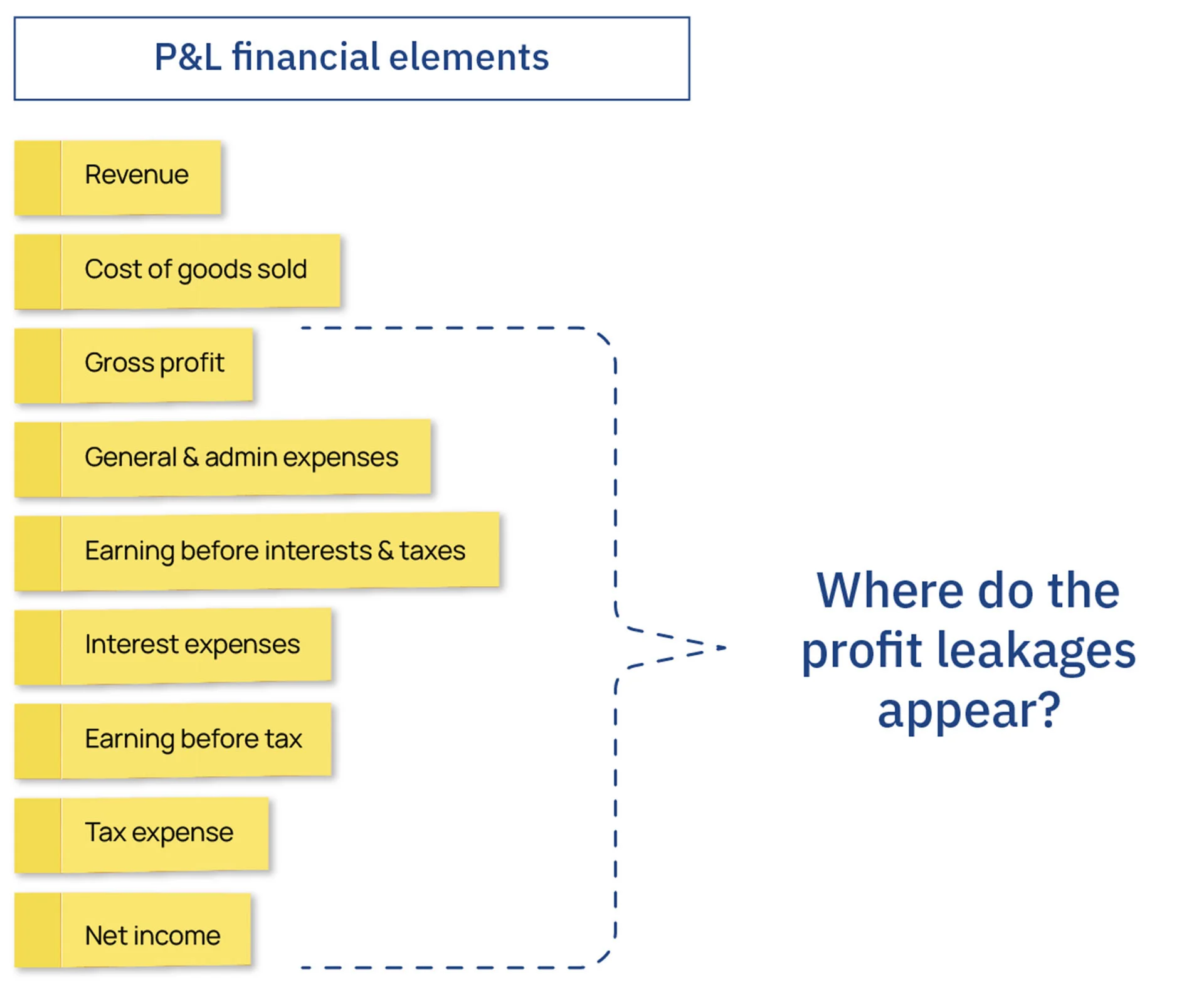

Having mapped the entire Valley Stream, it is easier to identify the profit leakage happening during every step in the value creation from each department as per the definition of profit leakages.

Having identified the department-wise profit leakages and quantified them with the financial numbers, it is appropriate to create accountability among the functional heads to work on improvement projects that will stop the profit leakage.

The projects, thus identified department-wise, can be allocated to teams, either cross-functional or functional, depending on the project's complexity and scope.

The success of the profit improvement program largely depends on the effectiveness of the reviews and governance, which tracks and monitors the improvement in the financial terms from the various projects.

Disadvantages of Choosing an Intervention Without A Diagnostic Study

- Choice of wrong organizational interventions.

- Inadequate consideration regarding the organization’s change readiness.

- Selection of low-impact improvement areas.

- Wrong assessment of resources and time frame needed for deployment.

- Failure to meet senior management mandates as expectations are not understood.

Why Diagnostic Study

The diagnostic study helps pinpoint organizational pain areas accurately and helps to ensure that efforts are invested only on the most promising high-potential areas having a direct linkage with the organization’s growth and profitability. The study helps the client to choose the right intervention that will unlock the potential of the company and deliver bottom-line results rapidly.

Business Benefits

- Identify profit leakage opportunities and avenues to maximize profitability.

- Assess opportunities for reducing losses and maximize shareholder returns.

- Design a bespoke Operational Excellence intervention focusing on client’s specific business needs.

- Garner enrolment of leadership team.

Benefit of the Study

- Brings out clarity on the focus areas.

- Enrolment of senior management team.

- Clear roadmap for excellence.

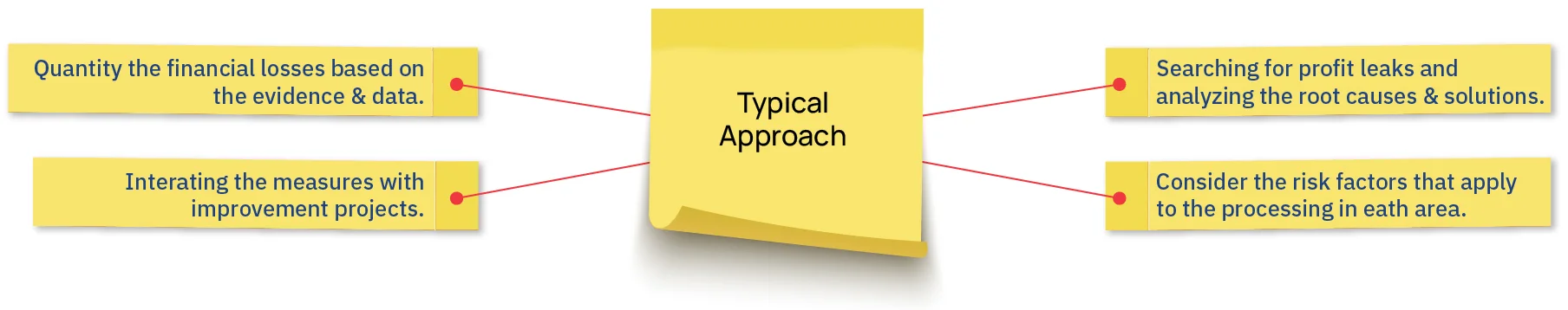

TYPICAL APPROACH

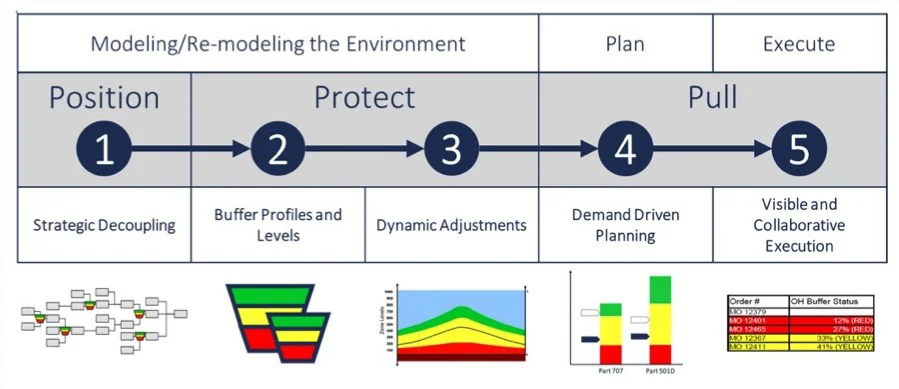

Demand Driven MRP Solutions

Demand Driven Material Requirements Planning (DDMRP) is NOT a silver bullet. DDMRP is based on sound flow-based principles to provide planning and execution performance improvements in variable environments where customer tolerance times are dramatically shorter than cumulative lead times. It is really that simple. The United States led the adoption of manufacturing information systems starting with MRP in the 1960s. These The United States led the adoption of manufacturing information system starting with MRP in the 1960s. These systems are expensive to purchase, to implement and to maintain. The value of these formal planning systems has always been based on the ability to better leverage the assets of a business systems are expensive. DDMRP is a methodology that gives people a step by step blueprint that is transparent, easy to interpret, intuitive, consistent, and sustainable. Demand Driven Material Requirements Planning is a proven method across a wide array of industries. It is quickly being adopted by a wide variety of leading companies across the world. It is intuitive, pragmatic and transparent. It is nothing short of a revolution in supply chain planning.rn how our Lean solutions can be tailored to your business.

What we do

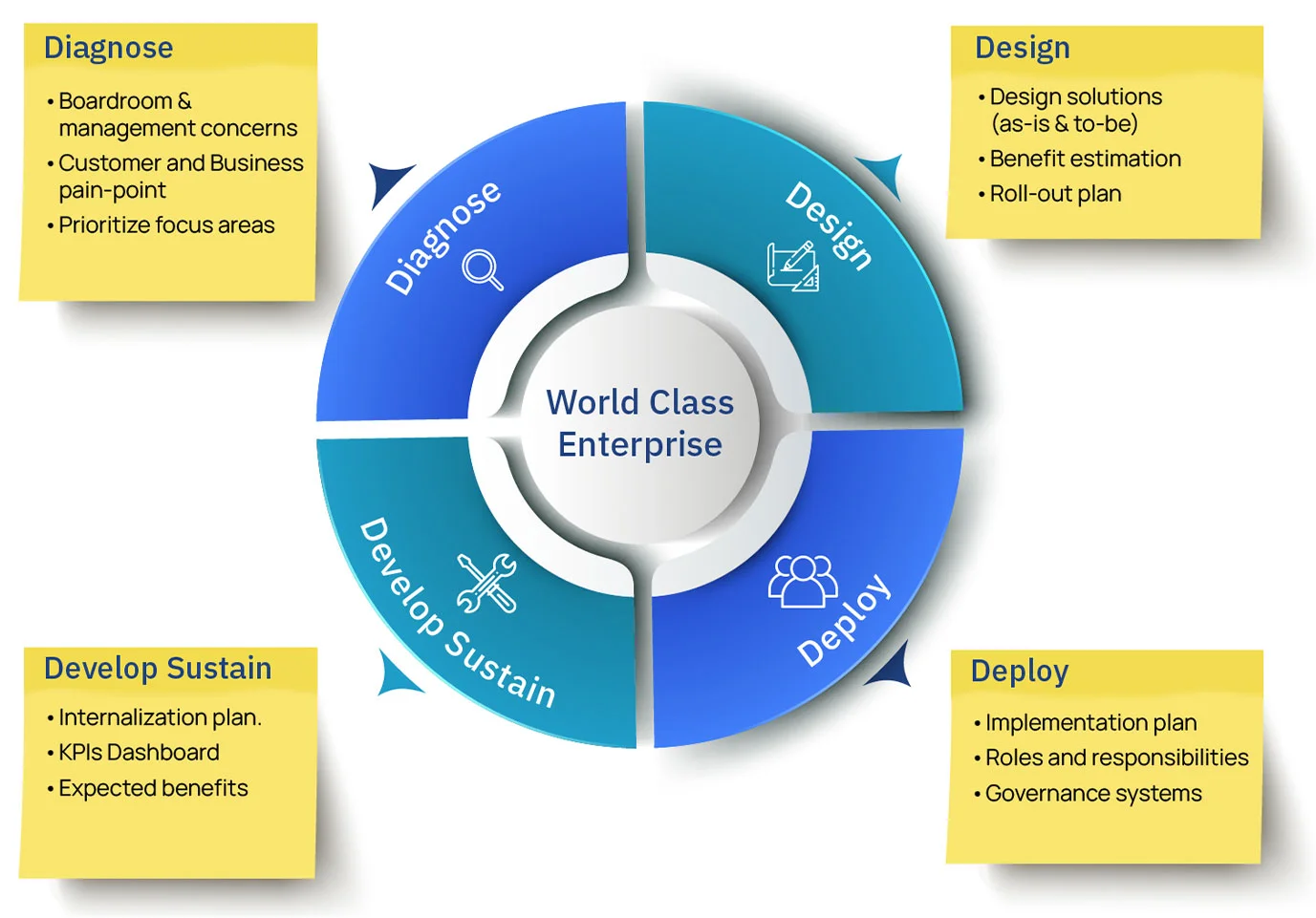

SSA is among the early proponents of DDMRP in the region. Our approach involves a 4 stage journey of Diagnose, Design, Deploy & Develop. As we work closely with the client’s planning & supply chain teams, we develop a bespoke solution that fits well with their current ground realities. We lay emphasis on creating a bedrock of excellence through training, coaching, mentoring and skill building across all layers of the organisation. We extend our support throughout the lifecycle of the project to ensure that the system is fully embedded and takes root. We realise that DDMRP is not just a planning methodology but a transformative approach that completely revolutionises the planning & execution system of the company. We therefore ensure that change management is very carefully orchestrated including development of internal teams that works alongside our consultants and eventually sustain the program long after we have gone.

How We Help Clients

Being an affiliate of the Demand Driven Institute (governing knowledge body of DDMRP), SSA has an outstanding team of consultants helping client all over India and Middle east to implement this system. SSA, as a partner on your journey towards being Demand Driven, helps you in every aspect of the journey - right from training the stakeholders on this methodology to preparing the groundwork needed to bring the system online. SSA, currently partners with B2Wise - an DDI certified DDMRP compliant software provider, in order to facilitate seamless integration of the DDMRP methodology with the current IT system.

Why Profit LeadershipTM?

When profits drop below desirable levels, there is pressure on the leadership team to cut cost as there is no way they can increase the price which may impede sales creating further pressure on profitability. In such circumstances, the top management would typically call for an emergency meeting of functional heads to cut costs on a war footing. The organization embarks on 'knee-jerk' cost-cutting exercises such as negotiations with suppliers to cut costs or resort to alternate sourcing, for better bargaining ability. The designers may initiate value engineering or material substitutions without adequate reliability evaluations, which in turn causes the product to fail in meeting customer requirements. Working capital reduction is initiated through inventory reduction without any system improvements or by delaying payments to suppliers.

Such measures may give a temporary cost reduction but may adversely affect the stability of the enterprise in the long run. Further, the cost may rise again after the emergency efforts are withdrawn. Thus, traditional cost-reduction efforts are mere "band-aid" solutions with unsustainable results. No one has scientifically established the right cost for a given organization. Unchecked inefficiencies over time cause costs to inflate and erode profits progressively until the situation becomes untenable, thus questioning the company's ability to survive.

What is a Profit LeadershipTM?

While the traditional profit & loss statement summarises income and expenses incurred and the resultant profit earned, it masks several inefficiencies of the firm and fails to paint the full picture of profit leaks.

Business Benefits

- Highlights blind spots of profit leakages for the business.

- Brings out clarity on the focus areas.

- Enrolment of senior management team.

- Creates a sense of urgency.

- Helps to benchmark best-in-class performance.

- Embrace global best practices.

Service excellence refers to the consistent delivery of exceptional customer service that exceeds expectations. It involves creating a culture of continuous improvement and adopting frameworks like Lean and Business Excellence to enhance service quality.

Additionally, Business Excellence frameworks, like the Baldrige Criteria or EFQM Excellence Model, provide a systematic approach to assessing and improving service performance. By integrating these frameworks, organizations can achieve service excellence by driving efficiency, reducing errors, enhancing customer satisfaction, and fostering a customer-centric mindset throughout the service journey.

Our Approach

Our consulting approach to service excellence is built upon a strong foundation of customer-centricity and a commitment to deliver tangible results. To achieve this, we apply "Lean" principles to simplify and accelerate processes. By identifying and eliminating waste, we streamline operations and enhance efficiency. Through process re-engineering, we eliminate redundant and non-value-adding activities, optimizing resource allocation and improving overall productivity.

We also focus on enhancing people's productivity by simplifying processes. By reducing complexity and providing clear guidelines, we empower employees to perform at their best and deliver exceptional service. This approach not only boosts efficiency but also cultivates a culture of continuous improvement.

Our consulting methodology is results-oriented, aiming to deliver both direct and indirect benefits. By streamlining processes and optimizing resource allocation, we generate direct cost savings. Additionally, our approach improves customer satisfaction, strengthens brand reputation, and drives customer loyalty, resulting in indirect benefits such as increased revenue and market share.

Throughout our consulting engagement, we prioritize collaboration and engagement with our clients. We work closely with their teams, ensuring knowledge transfer and fostering a sense of ownership in driving service excellence. Our consulting approach is tailored to the unique needs of each organization, recognizing that service excellence is a journey that requires ongoing commitment and adaptability.

Our 4D Approach for Service Excellence

Business Benefits

Implementing Service Excellence brings numerous business benefits. It enhances customer satisfaction, leading to increased customer loyalty and retention. This, in turn, drives revenue growth and improves market share. Service excellence also boosts brand reputation, attracts new customers through positive word-of-mouth, and reduces operational costs through process optimization and efficiency improvements.

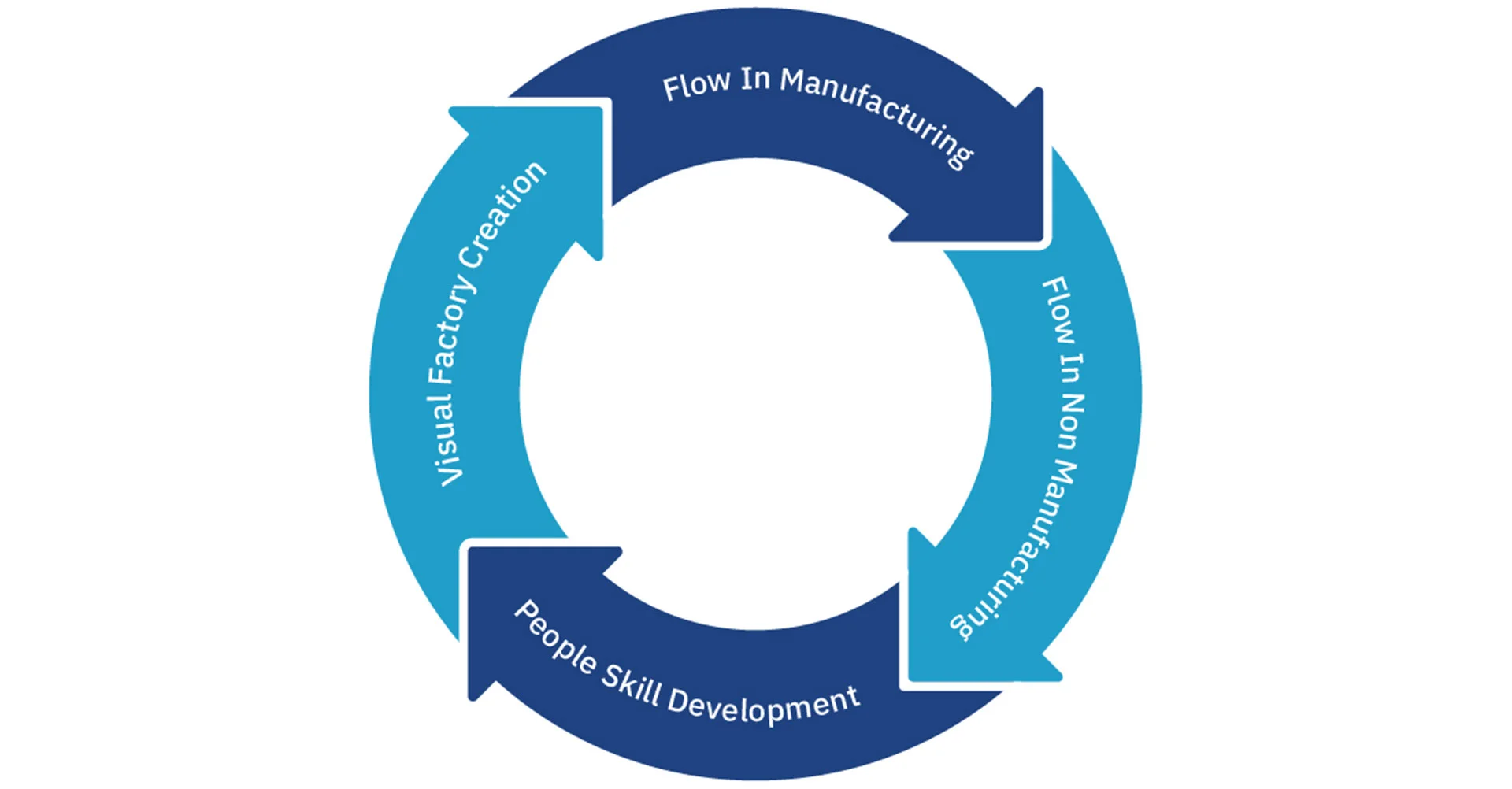

Manufacturing excellence encompasses the pursuit of operational excellence and continuous improvement in manufacturing processes. The application of Toyota Production System (TPS) and flow-based manufacturing systems plays a vital role in achieving this goal. TPS, focuses on eliminating waste, optimizing flow, and promoting a culture of continuous improvement.

By implementing TPS, organizations can streamline operations, reduce inventory, enhance quality, and increase productivity. Flow-based manufacturing systems prioritize smooth and efficient material flow, reducing bottlenecks and improving throughput. These approaches enhance efficiency, reduce lead times, minimize defects, and increase overall customer satisfaction, ultimately driving competitiveness and success.

Our Approach

Our consulting approach for manufacturing excellence is designed to address various aspects critical to achieving optimal performance. Here's a brief overview of our strategies for each focus area:

We analyze the manufacturing value stream, identify inefficiencies, and implement flow improvements, layout optimizations, and take-time based manufacturing techniques to enhance productivity and throughput.

We help organizations implement robust quality control systems, improve process controls, and enhance product design to minimize rejection rates and reduce the need for rework and reprocessing.

By conducting a thorough analysis of the value chain, we identify opportunities to reduce lead times, eliminate non-value-added activities, and enhance overall delivery performance.

We assist in establishing reliable data systems that capture critical manufacturing metrics, enabling real-time monitoring and informed decision-making for continuous improvement.

We focus on empowering the workforce through targeted training and certification programs, fostering a culture of continuous learning, and boosting employee morale and productivity.

We guide organizations in implementing lean manufacturing principles, such as 5S, visual management, and waste reduction techniques, to improve efficiency, reduce costs, and create a culture of continuous improvement.

We work with organizations to align all support functions, including HR, finance, procurement, and maintenance, with lean manufacturing principles, ensuring a cohesive approach and maximizing the benefits of lean initiatives.

We assist in establishing efficient material and resource planning systems, optimizing inventory levels, minimizing stockouts, and reducing lead times to enhance operational efficiency.

We help organizations implement robust quality management systems, focusing on defect prevention, root cause analysis, and continuous improvement, leading to improved product quality, customer satisfaction, and reliability.

We support organizations in developing standardized processes, work instructions, and performance evaluation systems to ensure consistent quality, enhance efficiency, and provide a foundation for continuous improvement.

Our consulting approach integrates these strategies to provide a comprehensive framework for achieving manufacturing excellence, enabling organizations to optimize their operations, enhance customer satisfaction, and drive sustainable growth.

Themes for Manufacturing Excellence

Business Benefits

- Implementing a manufacturing excellence initiative yields significant business benefits.

- Improved productivity and throughput lead to increased output and reduced costs.

- By reducing rejection, rework, and reprocessing, organizations save time and resources.

- Enhanced delivery performance through lead time reduction boosts customer satisfaction and loyalty.

- Developing an adequate data system enables informed decision-making and drives continuous improvement.

- Employee morale building promotes a motivated and engaged workforce.